PROJECT DESCRIPTION

The IPA 2013 program provided for the construction of wastewater treatment plants from the existing blocks B1 and B2, as well as the future block B3, and their flue gas desulfurization plants.

This project will solve the discharge of wastewater into the Mlava river and significantly reduce the negative impact of the operation of TPP Kostolac B on the environment.

WORKS DESCRIPTION

The project consists of 4 plants with a total capacity of 170 m3/h:

-

Wastewater treatment plant from flue gas desulphurization (FGD) and chemical water preparation (WWTP ODG/HPV)

-

Oily and HFO wastewater treatment plant (WWTP U);

-

Sanitary waste water treatment plant (WWTP S) and

-

Storm water treatment plant (WWTP Storm)

WWTP ODG/HPV

Applied technology consists of Water line: pretreatment of FGD wastewaters by precipitation of sulfate and magnesium ions by lime dosing; egalization (mixing of FGD and HP wastewaters); chemical treatment (coagulation, flocculation and pH adjustment), with additional settlement and removal of heavy metals of waste waters in lamella clarifiers; final neutralization before outlet to the recipient,and Sludge Line: transport from primary settlement tank and lamella clarifiers to final sludge thickener, chemical dosing and sludge treatment by dosing of polyelectrolite and using centrifuge unit resulting with sludge cake of minimum 25% of dry matter.

The capacity of the facility is 2x45 m3/h=90m3/h. The facility is equipped with an automatic sampler, automatic control and management of the facility work. Facility is designed to provide automatic control of all separate WWTPs.

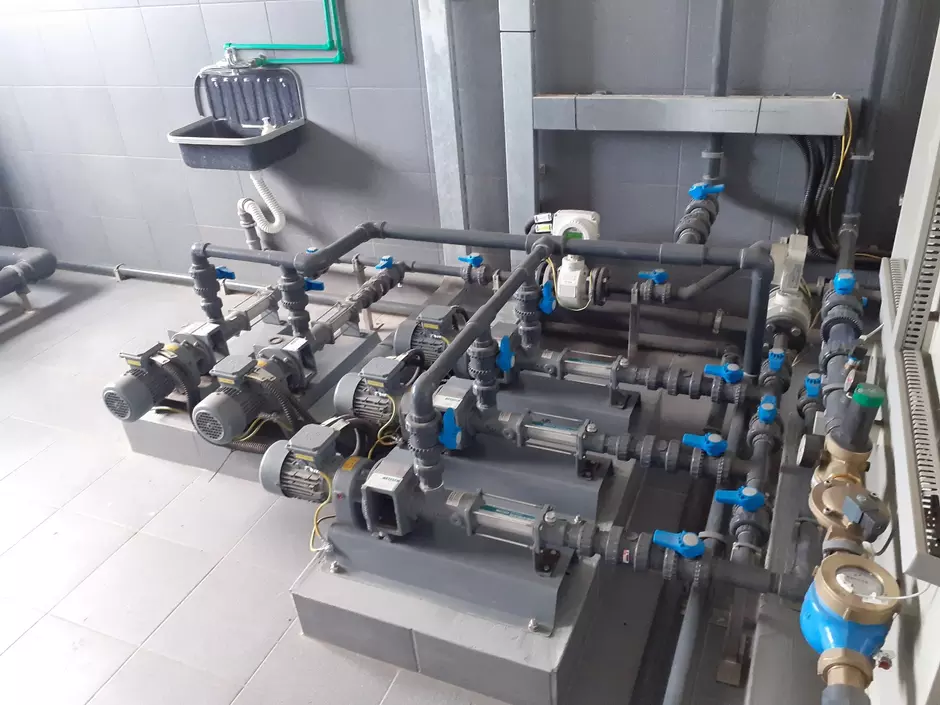

WWTP U

Applied technology consists of Water line: treatment of heavy oily wastewater at the API separator, egalization (mixing of oily and pretreated heavy oily waste waters), chemical treatment (coagulation, flocculation and pH adjustment), flotation (in Dissolved air flotation unit – DAF of the capacity of max 35m3/h) and final neutralization before outflow to the recipient and Sludge line: transport of sludge from the API separator and DAF units to the sludge tank, chemical conditioning of the sludge with polyelectrolyte and sludge dehydration in the centrifuge.

The capacity of the facility is 2x30 m3/h=60 m3/h. The facility is equipped with an automatic sampler, automatic control and management of the facility work.

WWTP S

Applied technology is SBR (Sequent Batch Reactor) with a capacity of 1.500 ES with automatic control and management of the facility work Sludge Lines include: pumping excess sludge from SBR into a tank for aerobic stabilization of sludge and aerobic stabilization of sludge with mixing and aeration in the sludge tank (sludge is periodically removed from the tank by trucks).

Maximal hourly capacity of WWTP-S is 21 m3/h SBR facility consists of coarse and fine screens with a capacity of 30 l/s; feeding pumps, 2 SBR reactors with mixers and aerators, a FeCl3 dosing system and an automatic sampler.

WWTP Storm

WWTP Storm Water consists of four oil separators with a total capacity of treatment of 1000 l/s. The total volume of separators is 19.000 l. All separators are in line with EN 858 standard.

EMPLOYER:

Government of the Republic of Serbia, Ministry of Finance (CFCU)

Employer’s address:

Sremska 3-5, 11000 Beograd, Serbia

TYPE OF THE CONTRACT:

YELLOW FIDIC

CONTRACT VALUE:

5,557,593.97 EUR

PERIOD OF EXECUTION OF THE WORKS:

09/2017 – 09/2021